Innovative Process Solutions for the Biodiesel Industry

A New Concept in Biodiesel Production

Simultaneous reaction and separation process:

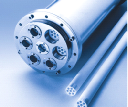

- Ceramic membrane technology

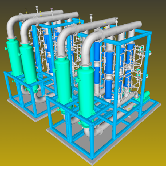

- Compatible with existing plant infrastructure

- Fully Scalable

- Capital Efficient (retrofit or new facilities)

Key Technology Attributes

- Low Catalyst usage

- Improved Glycerin Quality (Low Ash content)

- Reduced Soap Formation (Higher yields)

- Feedstock Flexibility

- No pre-treatment for feedstocks (< 5% FFA content)

(waste cooking oils, yellow grease, Jatropha, waste corn oil and algae)

- Use virgin feedstocks with reduced physical refining/degumming

(soy, rapeseed, canola)

- Reduced Processing Costs

- reduced catalyst usage

- reduced requirements for up and down stream processing

Setting a New Standard for Quality

Enhanced Product Quality

- Ultrafiltered product with no particulates

- Low monoglyceride levels ( <0.4 wt%) without costly distillation.

- Low sterol glucoside levels, reduces/eliminates need for use of absorption technologies

- Eliminates Cold Filter Plugging issues across the spectrum of feedstocks

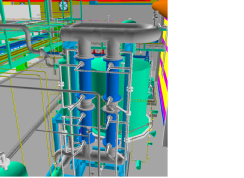

Biodiesel Membrane Reactor

BDR’s patented biodiesel membrane reactor offers a radical change in process operations and biodiesel product quality utilizing virgin oils, high FFA (free fatty acid) oils and next generation feedstocks. Our propriety membrane reactor system produces high quality biodiesel that surpasses industry quality specifications and can be configured to provide significant capital, operating and input cost savings for our customers.

How it works...

How it works...